SOLUTIONS FOR EVERY CONTAINER!

Shrink Tunnels Collection

G7 Shrink Tunnel

Phase Fire G7 is the perfect tunnel for tamper evident banding. It implements a tapered heating process that shrinks plastic safety seals evenly, giving your bottle a professional look.

What Is a Shrink Tunnel?

Heat Shrink Tunnel Oven - Accutek Packaging Equipment Companies

Request Free Consultation

Would you like to have a free consultation from one of our professional advisers? Just submit your details in given field and our experts will be in touch with you. You can ask for any suggestions about your business. We will exceed your expectations

Many large businesses are already reaping the benefits of a commercial solar installation. These innovative companies are defining the way future businesses will incorporate solar energy and are showing how it is a good fiscal decision. Here are some major global companies that have made the switch to solar including: Target, Apple, Macy’s, Intel, and Ikea …

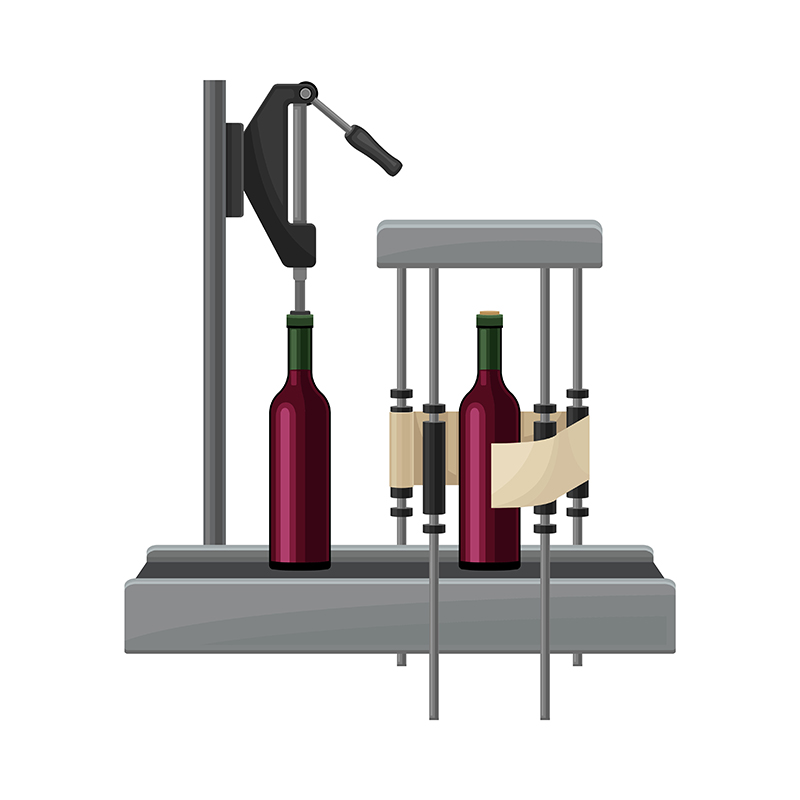

The backbone of every packaging line is the conveyor system that moves the product through the various stages of the production process. Typically, the product sits on a moving belt to get from point A to point B, but occasionally it is necessary to have access to the top or bottom of a container, a bottomless conveyor solves this requirement …

Accutek Packaging Equipment Companies, Inc, one of the largest packaging machinery manufacturers in the United States, is a leading developer and manufacturer of complete packaging solutions. Accutek Packaging Equipment Companies offer a wide variety of bottle filling, capping, and labeling machines. We pride ourselves on being able to support startup companies …